カーボンニュートラル実現に向けたキーテクノロジーの1つである次世代電池、さまざまな機能を持ったナノスケールの機能性粒子、5G・6G通信システムや環境対応車の普及、先進運転支援システム (ADAS)の進歩を背景に超小型化・高信頼性が求められるMLCCをはじめとする受動部品、DXによる質の高い医療、AI・デジタル化の進む医療機器など、社会のあらゆる分野で我々のコーティング技術に期待が集まっています。

MLCC/MLCI/バリスタ/サーミスなど受動部品における次世代誘電体シート成形、内部電極⼯程、両端⼦‧多端⼦の外部電極塗布及び塗布前後⼯程に関するプロセス技術‧装置‧治具‧受託サービスをご提供。世界最⼩サイズ0201mm〜等、弊社の特許技術‧ユニークなプロセス技術がお客様のご要望にお応えします。

電池原料や磁性材料など各種粉体・最先端デバイスの複雑な表面形状にも、有機・無機(金属、化合物、酸化物、窒化物)の1nm~1µmの緻密な成膜が可能です。ガスバリア膜、耐腐食膜、導電膜、絶縁膜などのその他様々な成膜に応用できます。

ロボット自らが物性評価・条件および組成の最適化の判断を行い、物質合成できるAIとロボット技術を駆使した「実験室の産業革命」です。それがセレンディピティ(予想外の発見)をもたらします。

※クリエイティブエーアイロボティクスは弊社グループ会社です。

液相から気相まで、お客様のニーズに合わせた製品を豊富に取り揃えています。

ご紹介しているもの以外でも、お客様のご要望内容によっては対応可能な場合も

多くございますので、まずはお気軽にご相談ください。

従来方式の電極塗布方式を技術改良し、お客様の製品や材料にあわせたプロセス条件、

ジグ、装置、開発サポート、受託塗布まで幅広く対応いたします。

※拡大してご覧ください。

※拡大してご覧ください。

液相技術の紹介動画です。

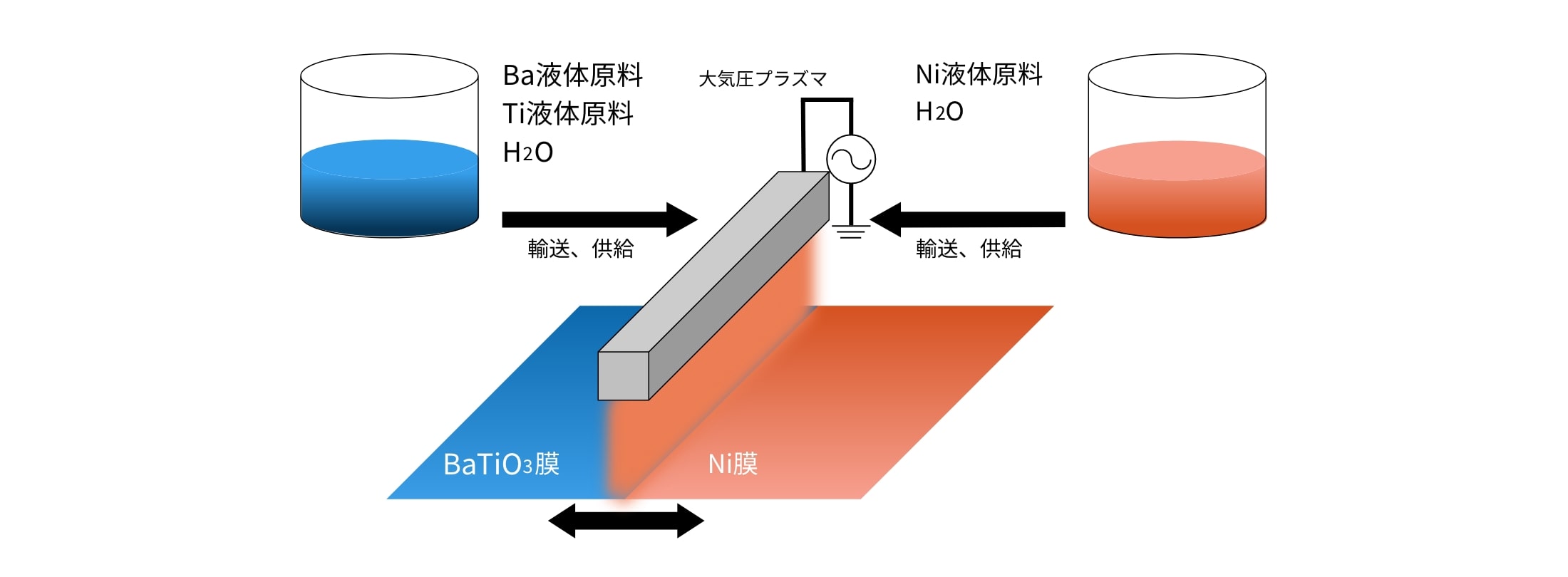

スラリーを使わない特別な液体原料を用いることにより、PETフィルム上に直接BaTiO3とNi電極パターンの積層構造(<100 nm)を形成するため、乾燥工程が不要な極薄誘電体グリーンシートを形成することができます。

※拡大してご覧ください。

『真空‧⼤気圧』ともに最適なメソッドで提案。有機‧無機(⾦属、化合物、酸化物、窒化物)の成膜が可能。

膜厚も1nm〜1μm の緻密で⾼品質な成膜が可能。

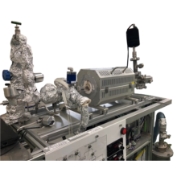

CMVA-500P

室温ALD装置

【応用例】

CMP-200

粉体成膜装置

【応用例】

CMVA-300

室温ALD装置

【応用例】

CMVD-100

室温DLC装置

【応用例】

CMVA-T100

高温ALD装置

【応用例】

気相技術の紹介動画です。

顧客ニーズに応える技術課題克服企業として、独創的なコーティング技術を通じてSDGsに貢献します。

| 社名 |

|

|---|---|

| 取締役 ・ 監査役 |

|

| 資本金 |

|

| 設立 |

|

| 事業内容 |

|

| 主要取引業種 |

|

| グループ会社 |

|

| 関連会社 |

|

| 販売代理店 |

|

| 監査法人 |

|

| 経営顧問 |

|

| 取引銀行 |

|

| 参加学会 |

|

| 共同研究 |

|

| 本社 |

|

| 研究開発拠点 |

|

〒113-0023 東京都文京区向丘二丁目28番12号ベルオーク本郷

電話:03-5946-8295 FAX番号:03-5946-8296

◆ 東京大学より車で2分

◆ 東京メトロ南北線 本駒込駅 徒歩4分

◆ 都営三田線 白山駅 徒歩7分

〒940-2128 新潟県長岡市新産東町38

電話:0258-89-8608 FAX番号:0258-89-8609

◆ 長岡技術科学大学より車で5分

◆ 新幹線・電車・バス/JR長岡駅大手口より車で約15分

◆ 関越道/長岡ICより車で約5分

〒992-8510 山形県米沢市城南四丁目3番16号

電話:0238-27-1603 FAX番号:0238-27-1603

◆ 山形大学 工学部構内(株式会社 Cool ALD 内)

◆ JR米沢駅より車で約10分